Mechanical power

The mechanical work horse is the path to prosperity.

Mechanical power is a mechanic that allows for the powering of different machinery through the harnessing of renewable energy (such as wind) via structures such as the windmill. Currently, it can be used to automate querns for milling, helve hammers to work iron blooms or smith metal plates, and pulverizers to crush materials into their powdered form.

Although it can be used to power a single machine, with a series of axle and gear connections, you can make what’s called a power train. This allows for the connection of multiple machinery at a time, working in tandem.

The Windmill

A windmill is a multi-block structure used to harness wind power and transform it into mechanical power. There are many possible designs for a windmill but factors to consider include:

- Location windspeed

- Height - for wind and clearance for sails

- Accommodation of various power train designs and equipment

- Amount of power needed to drive attached equipment

Detailed information on the windmill can be found on the windmill page.

Power Train

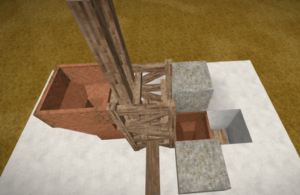

A series of interconnected axles, gears, brakes and other mechanisms that allow for an uninterrupted flow of mechanical energy through multiple machines at the same time.

Materials required for a Powertrain

Wooden Axles Used to transmit the wind power in a straight line. These may be placed vertically or horizontally in any of the cardinal directions.

| Ingredients | Crafting Recipe |

|---|---|

| Hammer Chisel log Fat |

Wooden Gears Allows the mechanical power to make a right angle turn by connecting a horizontal axle to a vertical one. Often needed depending on the design of the power train.

| Ingredients | Crafting Recipe |

|---|---|

| Hammer Saw Chisel Stick (2x) Log Resin Fat |

Brake Can be used to apply a lot of resistance to the mechanism in order to bring the entire train to a halt.

| Ingredients | Crafting Recipe |

|---|---|

| Hammer Chisel Log Wooden Axle Resin (2x) |

Clutch and Transmission

When placed together can be used to interrupt flow of energy to a specific branch of the powertrain.

| Ingredients | Crafting Recipe |

|---|---|

| Hammer Saw Chisel Boards (8x) Sticks (8x) Log Resin (2x) Fat |

| Ingredients | Crafting Recipe |

|---|---|

| Hammer Saw Chisel Boards (8x) Angled gears (2x) Resin (2x) Fat |

Input and output

Input and output is handled using chutes, hoppers and optionally chests. Hoppers accept multiple stacks of input items, which are then transported via chutes towards the input slot of an eligible block. A special type of chute, the Archimedes screw, can transport items upward provided it is powered.

Hopper (optional):

Used for material input/output. Crafted directly from copper plates.

| Ingredients | Crafting Recipe |

|---|---|

| Copper plate (3x) |

Chute (optional):

Used to direct materials from hoppers into chests or other containers (or the quern itself). These blocks can be placed directionally, with the output facing away from the player. Chutes are crafted from chute sections, which need to be crafted on an anvil with copper ingots, by hand or with the help of a helve hammer. As even the straight chute needs at least two sections, a minimum of two copper ingots is necessary for one chute.

Chest (optional):

Can be placed on top of a straight chute above the quern to direct materials into the quern input slot

| Ingredients | Crafting Recipe |

|---|---|

| Boards (8x) |

Automated Machinery

Milling

For mechanized milling, the quern must be attached to a windmill. With a full complement of sails, the quern will grind materials at wind speeds as low as 25%. Mechanized or not, querns enable the player to grind grain, as well as some minerals into their grinded forms.

Materials required for automated milling

Quern

Used to grind grains, stones, and minerals into powdered form.

| Ingredients | Crafting Recipe |

|---|---|

| Rock (4x) Sticks (2x) |

Automated Quern Train

The quern must be powered by connecting the incoming axle on the top or bottom of the quern. The quern cannot be powered by connecting the axle to the side of the quern. For maximum efficiency, connect the power input axle to the bottom of the quern. Automating input/output using hoppers and chutes is optional.

- Input: Placing a hopper above the quern inserts items into the input slot of the quern. If the quern is powered from the top, input cannot be automated. Alternatively, a straight chute with a chest above the chute can be used to feed the quern input slot from the top and is 4 copper cheaper than using a hopper for input.

- Output: Placing any item in the output slot will block the output, causing product items to drop out of the sides of the quern. To collect items, hoppers can be fed into chests. Place the hopper at the level of the block supporting the quern, not next to the side of the quern itself. If the hopper, or any block for that matter, is placed next to the side of the quern, this placement will prevent the quern from producing items}. Further, if the quern tries to output an item but the side is blocked, it will restart grinding the item. This means placing one block adjacent to the quern will reduce efficiency by 1 quarter.

Smithing

For mechanized smithing, the windmill is attached to a helve hammer. With a full complement of sails, the helve hammer will function, albeit slowly, at wind speeds as low as 30%. It can help the player in processing iron blooms and blister steel, as well as making plates of any metal type.

Materials required for automated smithing

Toggle:

Connects the powered axle to the helve hammer base

| Ingredients | Crafting Recipe |

|---|---|

| Hammer Chisel Boards (8x) Wooden axle Resin Fat |

Helve hammer base:

Holds the helve hammer, connects the hammer arm to the power circuit.

| Ingredients | Crafting Recipe |

|---|---|

| Hammer Chisel Boards (3x) Resin |

Brake (optional):

Placed after the helve hammer base, stops the hammer when not in use.

| Ingredients | Crafting Recipe |

|---|---|

| Hammer Chisel Log Wooden Axle Resin (2x) |

Automated Helve hammer train

The helve hammer must be powered by connecting the incoming axle on the left or right of the toggle and cannot be powered by connecting the axle to the top or bottom of the machine.

- The toggle must be placed adjacent to the helve hammer base. The toggle places sideways, be sure to orient the toggle such that the square frames abut the block intended for the helve hammer base. The input axle cannot be placed on the frameless sides of this block.

- The helve hammer base should be placed with the long arm of the triangular support and crossbeam facing the direction the payer intends to place the hammer. The sloped sides of the base are the back of the block, and the helve hammer will place directionally. Place an anvil three blocks away from the base, and then add the helve hammer onto the base. When placed correctly, the helve hammer should rest on the anvil when not in use. When placed on the base, the helve hammer requires two blocks to move freely through its arc.

- The brake (optional) can be placed on the other side of the helve hammer base.

Crushing

The pulverizer allows to crush certain stones and minerals into fine powder to be used for steel making. There is no other way to obtain these materials, thus mechanisation is necessary.

Materials required for a pulverizer set up

2 Pounder Caps:

Reinforces the pounders and makes them crush the materials faster. Made by smithing on an anvil.

Pulverizer Frame:

Holds the pulverizer pounders and connects them to the power circuit.

| Ingredients | Crafting Recipe |

|---|---|

| Saw Rock Boards (x42) |

Pulverizer Toggle:

Connects the powered axle to the pulverizer frame. Can only be crafted with a bronze or higher tier metal plate.

| Ingredients | Crafting Recipe |

|---|---|

| Hammer Chisel Wooden Axle Metal Plate |

2 Pulverizer Pounders:

The mobile part of the machine that does the pounding.

| Ingredients | Crafting Recipe |

|---|---|

| Hamer Chisel Log |

Hopper (optional):

Used for material input/output. Crafted directly from copper plates.

| Ingredients | Crafting Recipe |

|---|---|

| Copper plate (3x) |

Chute (optional):

Used to direct materials from hoppers into chests or other containers. These blocks place directionally, with the output facing away from the player.

Automated Pulverizer train

The pulverizer must be powered by connecting the incoming axle on the left or right lower block of the frame structure. The toggle needs to be placed in the lower frame block. The pulverizer takes up a total of 4 blocks vertically, two for the frame itself and two more for the moving pounders.

The pulverizer pounders need to be placed in the frame block, and both have to be placed for the machine to work. After placing them, pounder caps of varying strengths - depending on the metal they are made of - can be attached. To add the caps, the player needs to have two cap items in their inventory in one stack, then

put the pounders with that stack. When changing caps, the previously used ones will be returned to the player.

Bauxite stones, quartz and olivine bits and ilmenite chunks can be placed two at a time under the pounders. The powdered materials will be thrown out at the block side opposite to the pounders. Please not that Ilmenite can only be crushed with pounders equipped with steel caps.

- Input: Placing a hopper above an elbow chute leading into the front side of the frame, where the two pounders are located, will insert items into the input slots of the pulverizer. Note that a hopper drops items slowly - to speed the process up, replace the hopper with a chest directly above the elbow chute leading into the front side.

- Output: Items will automatically be thrown out the back side of the frame, opposite of the two pounders. To collect items, hoppers can be fed into chests, or into a system of chutes to direct output to one chest. Place at the level of the block supporting the pulverizer, not next to the side of the frame block itself. If the hopper, or any block for that matter, is placed next to the back side of the pulverizer, this placement will block the normal output slot, and the items will instead be thrown out to the two blocks to the right and left of the block behind the frame block. To optimize the automated output, leave the block directly behind the lower frame block open, place blocks to the left and right and a hopper below. This way, the items thrown out cannot deviate to the side and will instead fall into the hopper.

Video Tutorials

| Explanation of Big Gear usage | Generall Mechanical Explanation |

|---|---|

| How to build a windmill and Helve hammer in version 1.13 | How to build a pulverizer in version 1.14 | How to automate a pulverizer |

|---|---|---|

| {{{title}}} | |

|---|---|