Alkohol brauen

Das Brauen von Alkohol umfasst zwei verschiedene Produktionsstufen, nämlich den relativ einfachen Gärungsprozess und den komplizierteren Destillationsprozess.

Alkohol

Bemerkenswert ist, dass Alkohol, der wenigstens einmal destilliert wurde, nicht verdirbt, sondern immer noch sättigt - daher ist es eine sinnvolle Strategie, überschüssige Zutaten in Alkohol umzuwandeln und zu lagern. Beachte, dass dies für ein paar Früchte nur gilt, wenn sie die zweite Stufe des Alkohol Brauens (Destillation) erreichen, während im Besonderen "Cider" noch immer verderben wird (weitere fermentierte Arten sind noch unbestätigt).

Das Trinken von Alkohol führt jedoch zu einer Beeinträchtigung des Sehvermögens - der Spielercharakter schwenkt mit dem Kopf von links nach rechts, was sich tatsächlich auf die Bewegung im Spiel auswirkt, da es schwierig ist, in einer geraden Linie zu gehen, ohne der vom schwenkenden Kopf gewählten Bewegungsrichtung aktiv entgegenzuwirken.

Die Menge und Qualität des getrunkenen Alkohols beeinflusst die Schwere und Dauer der Beeinträchtigung.

Fermentierter Alkohol

Fermentierter Alkohol bietet sowohl Sättigung als auch Nährwert in der Obst-Kategorie - unabhängig davon, ob das Zutaten Obst war oder nicht. Einige fermentierte Alkohole verderben wie ihre Zutaten (z.B. alle Ciders).

Das in der Tabelle genannte Verhältnis bezieht sich auf die Menge an Zutaten im Vergleich zur Menge des erhaltenen Alkohols. Die Zeit bezieht sich auf die Dauer, die die Zutaten in einem Fass versiegelt werden müssen.

Jede Alkoholsorte und der Herstellungsprozess sind weiter unten detailliert beschrieben.

| Objekt | Sättigung pro Liter | Nährwertkategorie | Verhältnis | Zeit | Hinweise |

|---|---|---|---|---|---|

| Met | 160 | Obst | 1:1 | 14 Tage | |

| Apfelwein | 160 | Obst | 1:1 | 7 Tage | |

| Kirschwein | 160 | Obst | 1:1 | 7 Tage | |

| Pfirsichwein | 160 | Obst | 1:1 | 7 Tage | |

| Orangenwein | 160 | Obst | 1:1 | 7 Tage | |

| Mangowein | 160 | Obst | 1:1 | 7 Tage | |

| Litschiwein | 160 | Obst | 1:1 | 7 Tage | |

| Granatapfel | 160 | Obst | 1:1 | 7 Tage | Im Grunde eine Granatapfel-Apfelwein, aber mit einem ausgefallenen Namen. |

| Birnenwein | 160 | Obst | 1:1 | 7 Tage | Im Grunde eine Birnen-Apfelwein, aber mit einem ausgefallenen Namen. |

| Blaubeerwein | 200 | Obst | 1:1 | 7 Tage | |

| Preiselbeerwein | 200 | Obst | 1:1 | 7 Tage | |

| Roter Johannisbeerwein | 200 | Obst | 1:1 | 7 Tage | |

| Weißer Johannisbeerwein | 200 | Obst | 1:1 | 7 Tage | |

| Schwarzer Johannisbeerwein | 200 | Obst | 1:1 | 7 Tage | |

| Saguarowein | 160 | Obst | 1:1 | 7 Tage | |

| Ananaswein | 160 | Obst | 1:1 | 7 Tage | |

| Dinkelbier | 160 | Obst | 5:1 | 14 Tage | |

| Reisbier | 160 | Obst | 5:1 | 14 Tage | |

| Roggenbier | 160 | Obst | 5:1 | 14 Tage | |

| Amaranthbier | 160 | Obst | 5:1 | 14 Tage | |

| Maniokbier | 160 | Obst | 5:1 | 14 Tage | |

| Brotfruchtbier | 200 | Obst | 1:1 | 7 Tage | Auch wenn es als Bier bezeichnet wird, verhält es sich wie ein Wein. |

Destillierter Alkohol

Vegrlichen mit lediglich fermentiertem Alkohol, bietet destillierter Alkohol die gleiche oder sogar eine geringere Sättigung und keinen Bonus auf den Nährwert. Es verursacht schlimmere visuelle Auswirkungen beim Verzehr, aber es verdirbt nicht mit der Zeit.

Zusätzlich ist destillierter Alkohol der erste Schritt, um Aqua Vitae (doppelt destillierter Alkohol) zu erlangen, der genutzt werden kann, um alkoholgetränkte Bandagen herzustellen.

Das in der Tabelle genannte Verhältnis bezieht sich auf die Menge an benötigten Zutaten im Verhältnis zu dem erhaltenen Alkohol. Die Zeit bezieht sich auf die Dauer, die der Kessel und Kondensator benötigen, um 1L destillierten Alkohol herzustellen.

| Objekt | Sättigung pro Liter | Quelle | Verhältnis | Zeit |

|---|---|---|---|---|

| Distillierter Met | 160 | Met | ||

| Essig | 160 | Apfelwein | ||

| Kirschbranntwein | 160 | Kirschwein | ||

| Pfirsichbranntwein | 160 | Pfirsichwein | ||

| Orangenbranntwein | 160 | Orangenwein | ||

| Mangobranntwein | 160 | Mangowein | ||

| Litschibranntwein | 160 | Litschiwein | ||

| Granatapfelbranntwein | 160 | Granatapfel | ||

| Birnenbranntwein | 160 | Birnenwein | ||

| Blaubeerbranntwein | 160 | Blaubeerwein | ||

| Preiselbeerbranntwein | 160 | Preiselbeerwein | ||

| Roter Johannisbeerbranntwein | 160 | Roter Johannisbeerwein | ||

| Weißer Johannisbeerbranntwein | 160 | Weißer Johannisbeerwein | ||

| Schwarzer Johannisbeerbranntwein | 160 | Schwarzer Johannisbeerwein | ||

| Saguarobranntwein | 160 | Saguarowein | ||

| Ananasschnaps | 160 | Ananaswein | ||

| Dinkel Whisky | 160 | Dinkelbier | ||

| Sake | 160 | Reisbier | ||

| Roggen Whisky | 160 | Roggenbier | ||

| Amaranth Whisky | 160 | Amaranthbier | ||

| Maniok-Wodka | 160 | Maniokbier | ||

| Brotfrucht-Wodka | 160 | Brotfruchtbier |

Fermentierung

Verschiedene Sorten der Grundzutaten können zu Alkohol fermentiert werden, indem sie in einem Fass für bestimmte Zeit versiegelt werden. Diese verschiedenen Grundzutaten resultieren in verschiedenen Sorten alkoholischer Getränke, jedes mit seinem eigenen Sortennamen:

- Met - hergestellt aus Honig

- Apfelwein und Wein - hergestellt aus verschiedenen Sorten von Obst und Beerensäften

- Bier - hergestellt aus verschiedenen Sorten von Mehl fermentiert mit Wasser

Alle Fermentierungsprozesse benötigen wenigstens ein Fass, einen Holzeimer oder Schüssel und die oben genannten Zutaten. Einige davon sind schwerer zu erhalten als andere, aber generell sollte das Fermentieren nicht begonnen werden, bevor das Metallzeitalter erreicht wurde (Fässer und Eimer benötigen eine Säge) und eine komfortable, sichere und gut ausgestattete Heimstätte vorhanden ist.

Mead

Apart from the barrel and bucket, the only ingredient required for mead is honey. Honey can be acquired from bee hives, to ensure a sufficient supply of honey for both brewing and other usage, it is recommended to follow the Beekeeping guide and build up a well developed beekeeping enclosure.

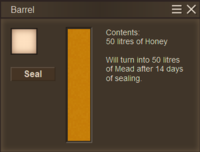

To ferment honey into mead, it simply needs to be transferred into an empty barrel and sealed. The tooltip inside of the barrels UI will inform about the resulting amount as well as the duration the barrel will need to stay sealed. For mead, the conversion from base ingredient to alcohol is 1:1, meaning even just one litre of honey will turn into 1 litre of mead. The sealing duration however is exactly 14 days regardless of the sealed amount. Since honey doesn't spoil, there is therefore no reason to ferment in small increments, instead the player could wait until gathering a full barrel.

Cider and Wine

Making cider and wine requires a bit more preparation before the fermentation process can start. Specifically, fruit can not be fermented in its raw state, it needs to be turned into juice first. This however requires a Fruit Press. Once fruit juice was procured from the raw fruit, the following process is much like the one for mead.

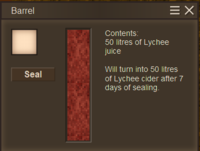

To ferment fruit juice into cider or wine, it simply needs to be transferred into an empty barrel and sealed. The tooltip inside of the barrels UI will inform about the resulting amount as well as the duration the barrel will need to stay sealed. For cider or wine, the conversion from base ingredient to alcohol is 1:1, meaning even just one litre of juice will turn into 1 litre of cider or wine. The sealing duration however is exactly 14 days regardless of the sealed amount.

Raw fruit itself will spoil rather quickly, as does the juice made from it. Cider and Wine will equally spoil at a slower pace, however they can both be further processed into distilled alcohol which will not spoil regardless of source material.

|

Protip:

To seal the barrel, the juice inside cannot have more then one decimal. For instance, a barrel with 1.13L cannot be sealed for fermentation, however a barrel with 1.1L can be sealed. |

Ale

To brew ale, a barrel, a liquid container as well as an amount of flour is required. Only specific types of flour can be used for fermentation, specifically:

- spelt

- cassava

- rye

- rice

- amaranth

Flax and sunflower flour cannot be used to ferment ale.

To craft flour, a quern is needed, which in turn requires full stone blocks and therefore a metal pickaxe. Since the quern can be powered by hand, automation is not required.

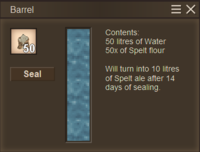

To ferment flour into ale, a barrel needs to be filled with water and flour in a 1:1 ration, meaning 1 litre of water requires 1 flour. However, the ingredients will not be turned into alcohol with the same ratio, meaning unlike for mead and cider, it requires more base ingredients to acquire the same amount of alcohol. The actual ratio is 5:1, which means it requires 5 litres of water and 5 flour to make 1 litre of ale - therefore 1 litre of water and 1 flour results in 0.2 litres of alcohol. This process can be done in 1 litre steps, however due to the long shelf life of flour there is no urgent need to turn flour into alcohol immediately.

The fermentation process takes 14 days regardless of the amount of ingredients.

|

Protip:

While breadfruit turns into an alcohol titled 'Ale', it does not actually follow the same mechanics of flour based ales and instead behaves like a fruit wine instead. |

Distillation

Requirements

The process of distillation first requires a boiler and condenser. Both of these are made from processed copper, tin and lead or silver - and therefore require the player to have at least reached the copper age, including a finished copper anvil.

Shopping List

For one set of boiler and condenser, the player would need:

- 7 copper plates = 14 copper ingots

- 1 soldering iron = 1 stick and 1 copper chisel (= 1 copper ingot)

- 7 Solder Bars = 2 ingots of either lead or silver solder alloy, as well as a saw with enough remaining durability

Soldering Iron

A soldering iron is a tool used, for the moment, exclusively to craft the boiler and condenser. It requires a stick and a copper chisel - keep in mind that the durability left on the chisel will be carried over to the soldering iron. Given that one crafting process including the soldering iron only takes 3 durability - and only 2 processes are needed for a fully working distillery - it is almost advisable to use an already used chisel with only around 6 durability left over for this.

Solderbars

Solderbars are, for the moment, exclusively used to craft the boiler and condenser. They require a saw of any metal type, as well as ingots made from one of the two available solder alloys - Lead Solder or Silver Solder Ingots. These ingots can be created through casting, combining tin with either lead or silver in the correct amounts:

- Lead Solder: Lead (45% to 55%) and Tin (45% to 55%)

- Silver Solder: Silver (40% to 50%) and Tin (50% to 60%)

Boiler & Condenser

Both of these are made mainly from copper and require a Soldering Iron made from copper as well, as seen above.

Process

The distillation setup includes a total of three steps, and should be done in a certain order to avoid placement headaches.

- The first object that should be placed is the boiler. Arrange it so there is at least one block space to one side of the boiler - this is where the condenser can be placed in the next step. Additionally, there needs to be room to access the boiler itself, since the third step of the setup needs a campfire to be placed below the boiler.

- The condenser can be placed while targetting one side of the boiler, and will then be put down on the block next to that side. It is technically possible to have more than one condenser attached to the same boiler, however only one condenser will be used at the same time.

- The next step requires a campfire to be set up under the condenser.

Press the sprint button while left clicking first the grass and then the firewood in place under the boiler. The campfire should only be ignited once the condensation process can start!

Once the setup is complete, the boiler needs to be filled with an alcoholic beverage - either fermented alcohol or once distilled alcohol - and the condenser needs to be filled with water. Before starting the process, a bucket needs to be placed under the condenser snout.

The boiler can be filled with up to 30 litres of the same alcohol, whereas the condenser can hold 10 litres of water at a time. The campfire below the boiler can take up to 4 pieces of firewood each time, which amounts to a burn time of 8 hours. At the moment, it is not possible to directly open the firepit GUI and input more than 4 pieces - nor is it possible to restock fuel during the process.

Therefore, a distillation can be started and then left to work on its own. The player only needs to return after 8 hours to restart the fire with new fuel - however, this will waste fuel, as explained below.

Before the condensation process starts, the boiler temperature needs to reach about 78°C, this will take 0.2h of the initial fuel time. The temperature of the boiler will not rise above 100°C. After the fuel is consumed or the alcohol has been processed, the boiler will show as "cold" and the campfire will be extinguished automatically. However, if firewood or alcohol is restocked fast enough, the campfire will ignite again automatically. The temperature will sink during the time the campfire is out, and will rise up again to reach 100°C.

Once the campfire has been fired through once, it does not require the full 4 pieces of firewood placed down to be started again, and therefore smaller amounts of alcohol can be processed without wasting too much fuel. Similarly, the remaining fuel time of a distillation process once all source alcohol is gone remains and can be used towards the next process.

Below is a table of required source alcohol, water and fuel to receive a certain amount of distilled alcohol. The time needed includes initial heating time and the firewood needed takes into consideration, that 4 pieces are needed to start the first fire - the second number in brackets displays the actual need.

| Source Alcohol | Water | Firewood | Time needed | Resulting Alcohol |

|---|---|---|---|---|

| 1L | 0.07L | 4 (1) | 0.3h | 0.1L |

| 10L | 0.5L | 4 (1) | 1.9h | 1L |

| 20L | 1L | 4 (2) | 3.8h | 2L |

| 30L | 1.5L | 4 (3) | 5.7h | 3L |

Video Tutorials

| General Brewing Explanation | Full guide from juice to alcohol |

|---|---|

| {{{title}}} | |

|---|---|